Collaborating Robots

Scroll

Easily optimize your production processes with collaborative robots

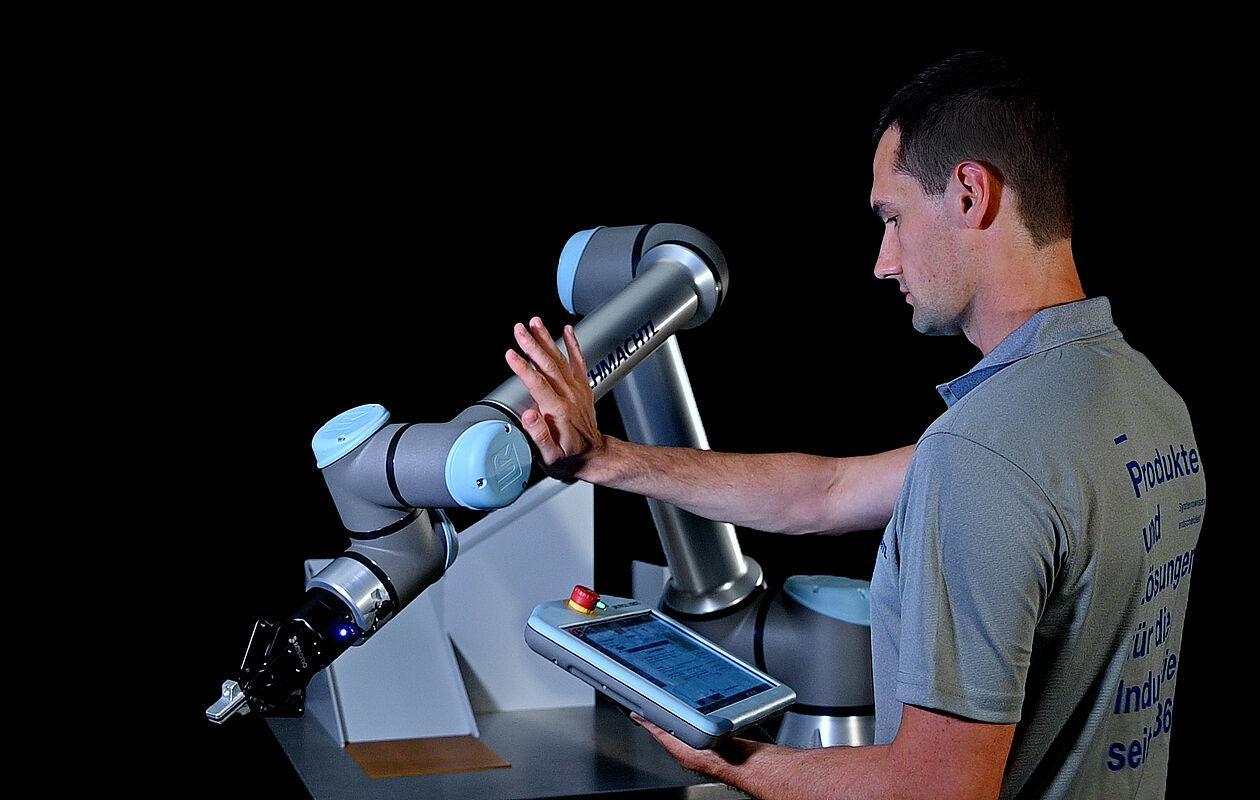

Universal Robots "Cobots" are collaborative robots that enable cooperation with humans, playing a crucial role in the automation of production facilities around the world. Collaborative here also stands for interaction without spatial separation between humans and machines.

Where are Universal Robots cobots used? Wherever humans perform heavy,monotonous,dirty and dangerous work on a daily basis in the production environment. By having the robot assist and/or take over daily tasks, the worker has more time for meaningful and supervisory activities. Cobots are used in a wide range of industries from mechanical engineering and automotive to pharmaceuticals, electronics and aerospace. Joint, collaborative and close cooperation between robots and humans increases process efficiency and production safety, enables automation of monotonous and hazardous work, and leads to a reduction in production costs

The Universal Robots e-Series stands for 'Empowering', 'Ease of use', 'Everyone', and 'Evolution'.

- Automated packaging and palletizing operations reduce costs

- Relieve employee workload through autonomously performed "Pick-and-place work" with intelligent image processing systems and grippers

- Quality testing through non-destructive test methods and 3D measurement of the cobot ensures product quality

- Handling of prototype and small series parts through direct connection with the injection molding machine

- Support of highly precise manufacturing processes with high variability thanks to individual adapter devices

Flexible Automatisierung

- Einfachen Programmierung & intuitives Setup

- Sehr geringer Zeitaufwand für die Inbetriebnahme

- Bis zu 5x günstiger wie Industrieroboter

- Geeignet für einfache bis hin zu extrem komplexen Anwendungen

Master the challenges of the future

- Gain a competitive advantage.

- Increase the overall quality of your products.

- Find a new answer to the shortage of qualified employees.

- Fast payback: average ROI of less than 1 year.

Herausforderungen der Zukunft meistern

- Verschaffen Sie sich einen Wettbewerbsvorteil.

- Erhöhen Sie die Gesamtqualität Ihrer Produkte.

- Finden Sie eine neue Antwort auf den Mangel an qualifizierten Mitarbeitern.

- Schnelle Amortisation: Durchschnittlicher ROI von weniger als 1 Jahr

Cobot & Man: A strong team!

- Increase of process efficiency and production safety.

- Relief of employees, through automation of monotonous and dangerous work.

- Leads to a reduction in production costs.

Cobot & Man: A strong team!

- Increase of process efficiency and production safety.

- Relief of employees, through automation of monotonous and dangerous work.

- Leads to a reduction in production costs.

Products

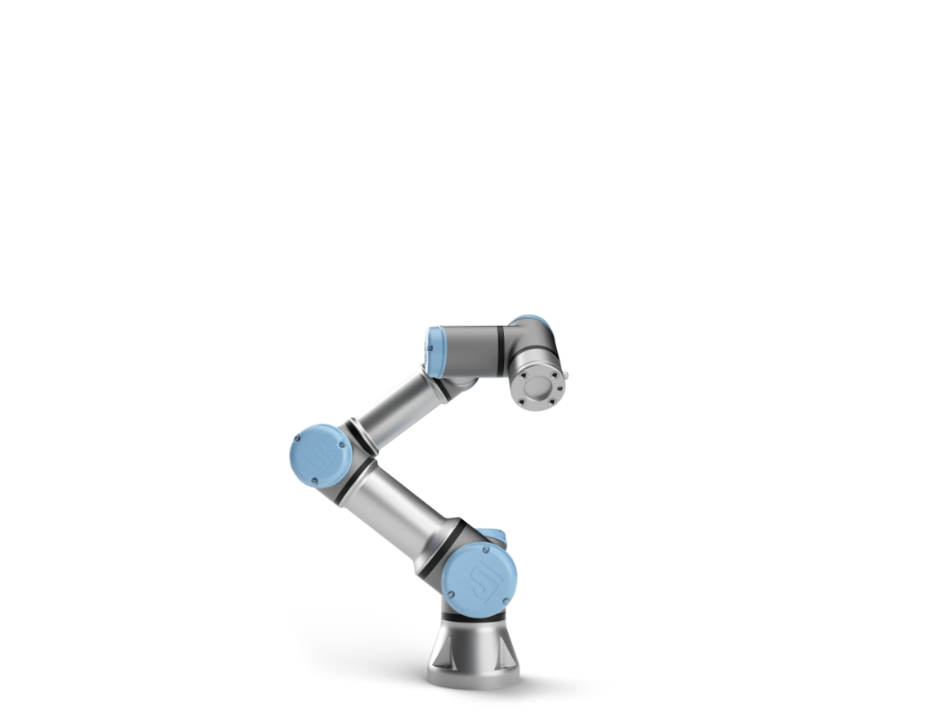

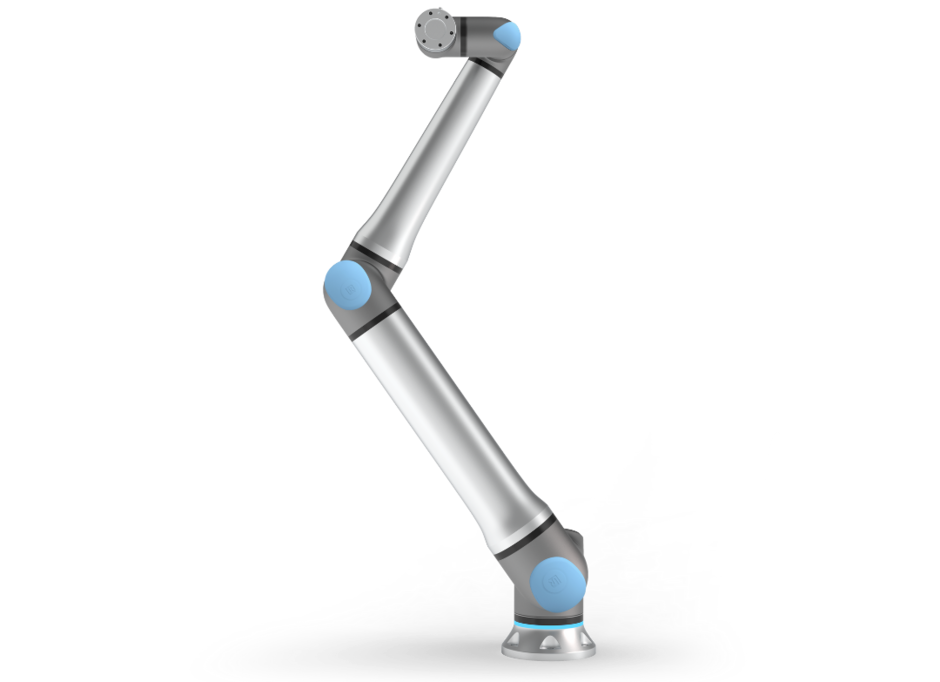

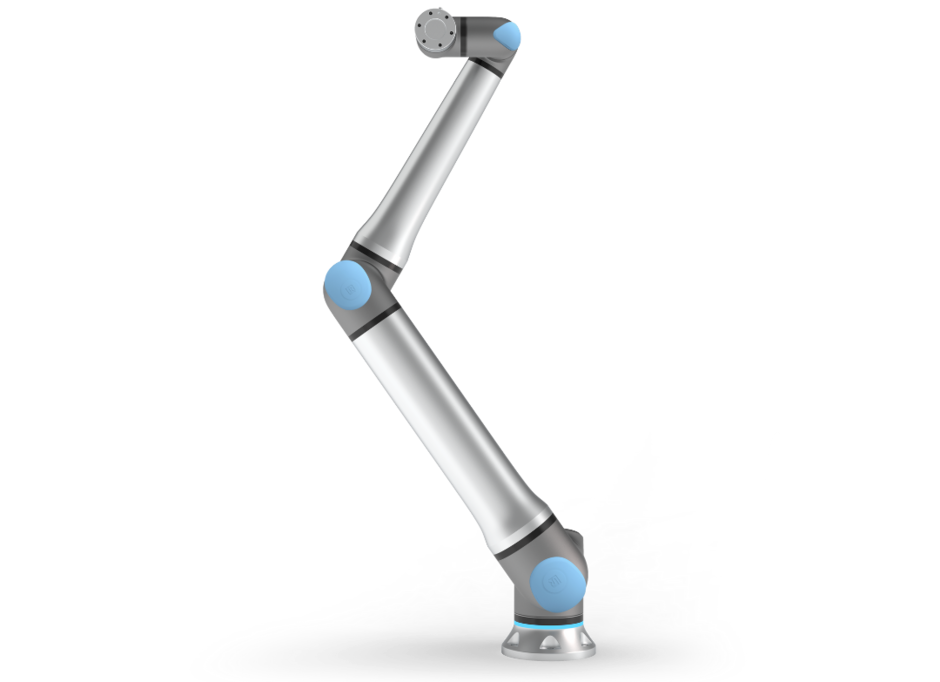

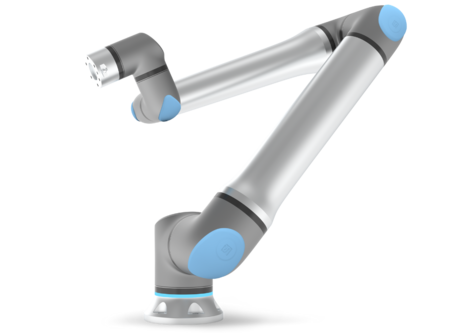

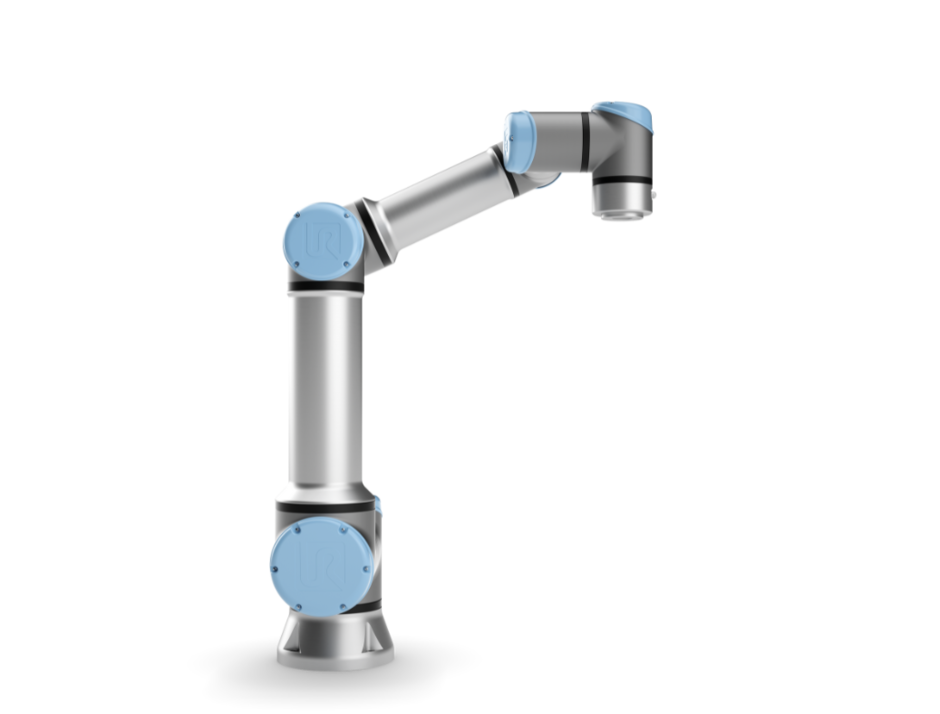

The e-Series family

In addition to a better specification compared to the previous series, this series is mainly characterized by the fact that the last joint is monitored with a force-torque sensor.

Now NEW UR16e

Features

- Payload 16 kg

- Range 900mm

- Handling heavy objects

- Material handling, CNC machine tipping

UR30

- Nutzlast: 30 kg

- Radius: 1300 mm

- Dank der Reichweite und Kraft ideal für Palettier-, Bohr- und Schraubaufgaben, sowie Maschinenbestückung.

Contact

Contact

Contact us for more information about our products and services. We are happy to assist you.